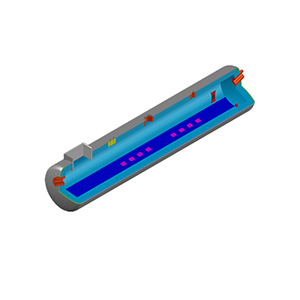

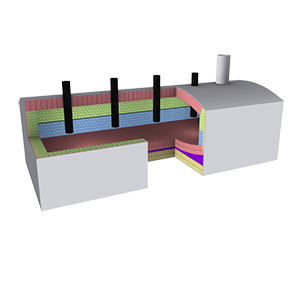

Convertor

Details

Recommendation

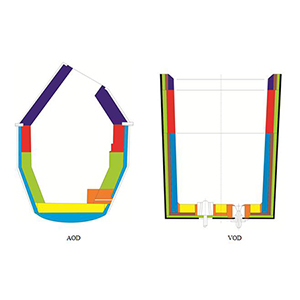

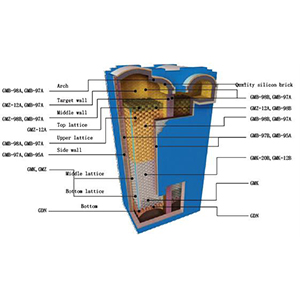

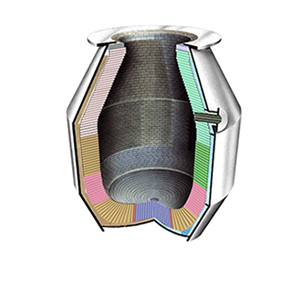

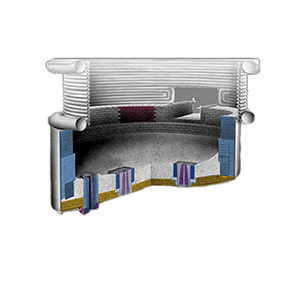

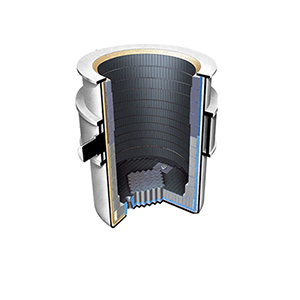

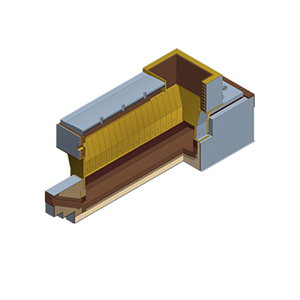

●Tuyere Slag Line Zone: Under very harsh working conditions, they are always being eroded by molten blister copper penetration, copper slag chemical reaction damage, matte SO2 gas proliferation erosion and oxygen spray process oxidation reduction reaction damage, high temperature hydration, refining process over heat reaction damage and spraying process temperature severe change and over heat liquid rigorous erosion, mechanical fatigue due to periodic operations. Only high chrome DMK and FMK products endure such vigorous damages.

●Working Lining: Due to periodic rotating operations, the working ling suffers chemical erosions and penetrations with copper slag, matte, SO2 gas proliferations etc., including temperature changing damages. All these erosions and damages are only less rigorous to the working linings, therefore medium grade chrome DMK, FMK and KAB products are recommended.

簡體(tǐ)中(zhōng)文(wén)

簡體(tǐ)中(zhōng)文(wén)