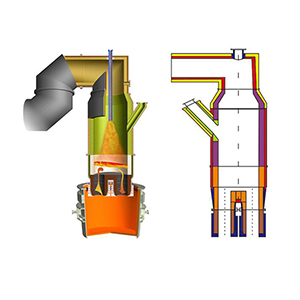

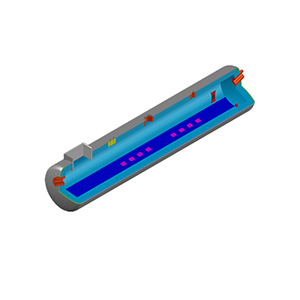

Coal Gasifier

Details

Recommendation

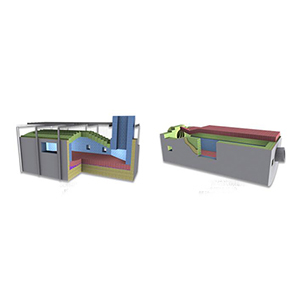

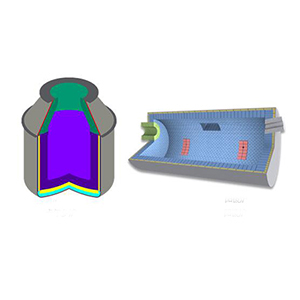

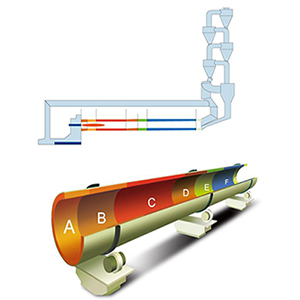

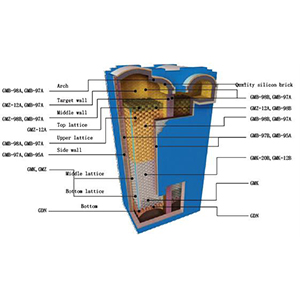

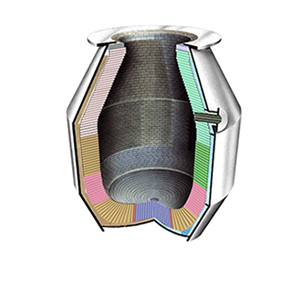

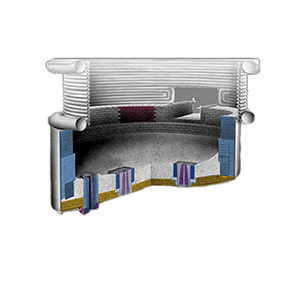

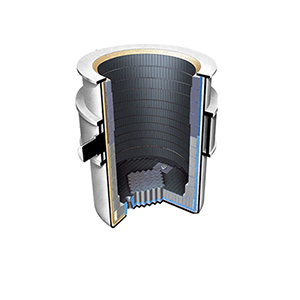

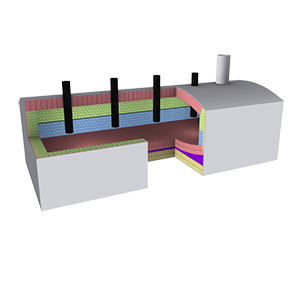

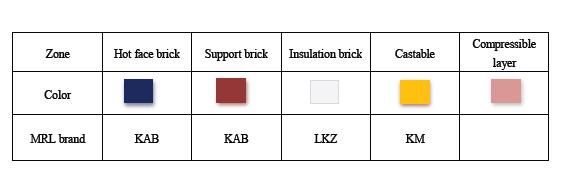

●Gasifier is high temperature and pressure equipment and refractory must be installed inside. Ordinary refractory can’t meet the application conditions of advanced gasifier. MRL’ high chrome brick can meet the demand of coal must pressurized gasifier on furnace lining.

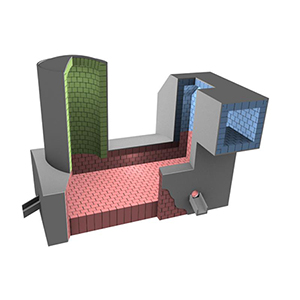

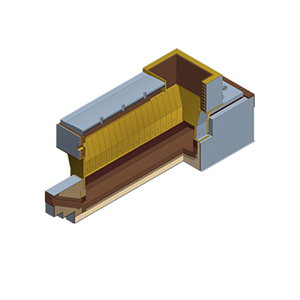

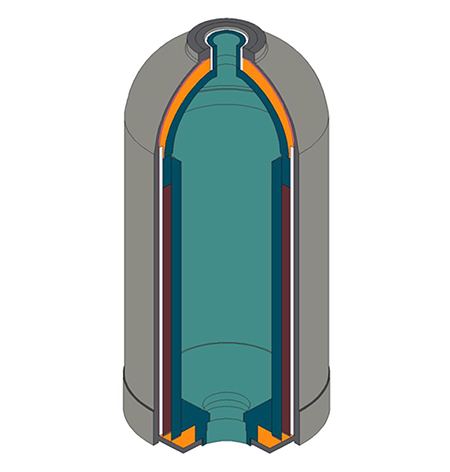

●Hot Face Brick: The quality of hot face brick directly affects the operation stability and service life. It must stand the splashing, abrasion and corrosion of coal, coke and slag at high flow under high temperature. It must have proper resistance to thermal shock and high temperature creep. Normally, KAB-90 is used here. For slag discharge and other critical parts, KAB-90S can also be used.

●Support Brick: Behind the hot face brick, it plays a vital mechanical support and protection to the gasifier refractory as a whole, which can be eroded by high temperature gas. The chrome corundum brick for supporting bricks has a high strength, and more than 12% of the chromium oxide increases the gas corrosion resistance of the product.

●Insulation Brick: Behind the supporting bricks, the alumina hollow ball bricks are used to heat the gasifier to keep the temperature of the outer wall at a set value. Alumina hollow ball brick is a good energy-saving material, in addition to low thermal conductivity. It also has good corrosion resistance.

●Castable: the castables are chrome corundum castables and alumina hollow sphere castables.

Chromium corundum castables are used for the dome and cone bottom. Compared with bricks, castables have the advantages with convenient construction, good integrity and good air tightness. Alumina hollow ball castables have the advantages of heat preservation and energy saving, and convenient construction.

●Compressible Layer: They are the alumina silicate fiber felt or ceramic fiber plastic. It is pasted inside the drum surface. It is low in volumetric weight, thermal conductivity and good in compressibility and has favorable insulation property.

- Prev:Glass Regenerator

- Next:Basic Oxygen Furnace

簡體(tǐ)中(zhōng)文(wén)

簡體(tǐ)中(zhōng)文(wén)